Demystifying GCode: Understanding the Language of CNC Machining

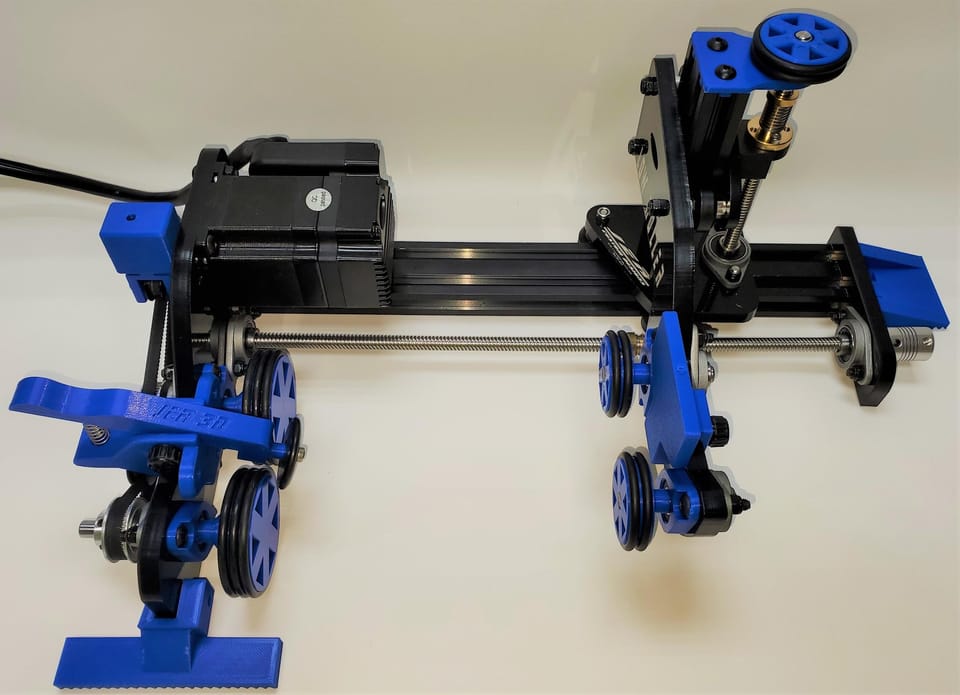

GCode is a programming language used to control CNC (Computer Numerical Control) machines, which are used in manufacturing to cut, shape, and drill various materials. It is a standardized language that is used to tell the machine what actions to take, such as the direction and speed of the cutting tool.

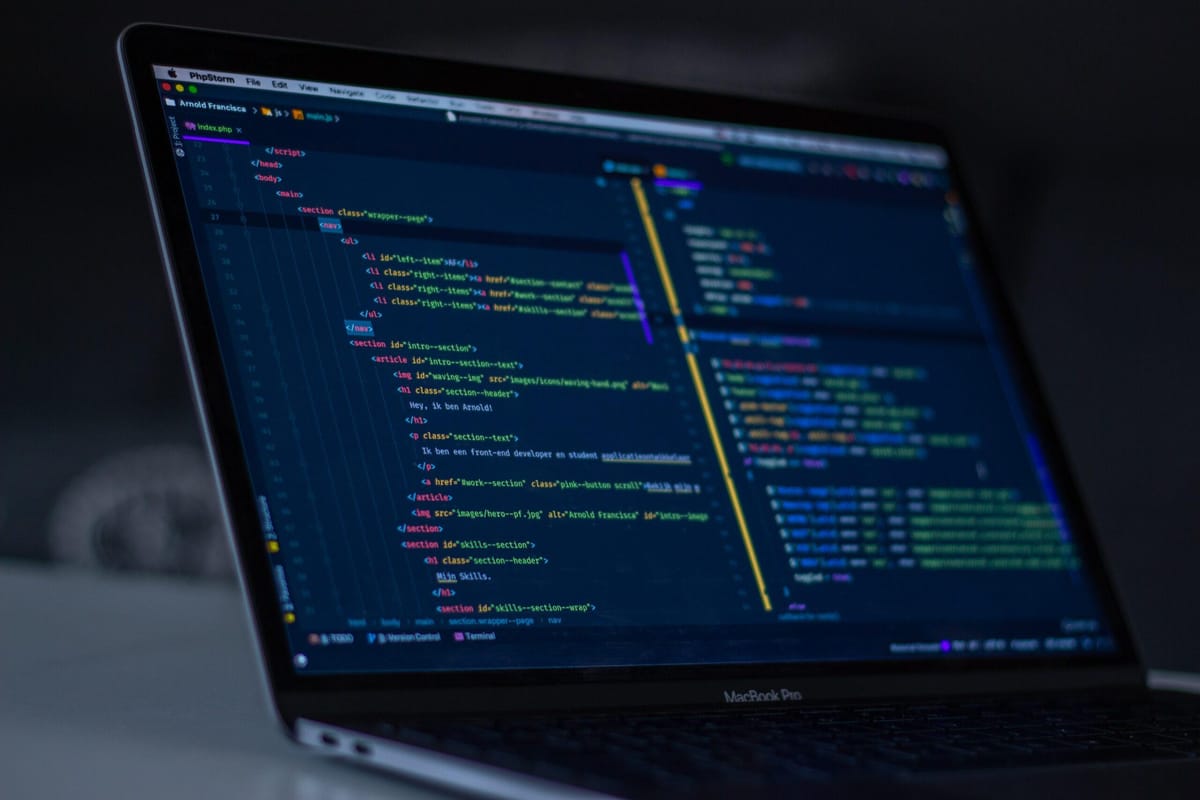

GCode is made up of a series of commands that are entered into a computer, which then sends the commands to the machine’s controller. The controller reads the commands and translates them into movements of the cutting tool. This process is often referred to as “toolpath.”

There are a variety of GCode commands that can be used, depending on the specific needs of the job. For example, G00 is a command that tells the machine to move quickly to a new location, while G01 tells it to move at a slower, more precise speed. Other common commands include G02 and G03, which are used to create arcs and circles, and G04, which is used to add a pause or delay to the program.

GCode is an essential part of the CNC machining process, as it allows for precise control over the cutting tool’s movements. It is also used in conjunction with CAM (Computer-Aided Manufacturing) software, which is used to create the toolpath based on a 3D model of the part being produced.

In addition to its use in manufacturing, GCode is also used in the DIY and hobbyist communities, as many small-scale CNC machines are available for personal use. These machines often come with their own software that generates GCode based on user input.

Overall, GCode is a powerful tool that allows for precise control over CNC machines, making it an essential component of modern manufacturing processes.