Understanding DC Excited Glass Tube CO2 Lasers

DC excited glass tube CO2 lasers are a popular type of laser used for a wide range of industrial, scientific, and medical applications. These lasers are known for their high-power output and excellent beam quality, making them ideal for applications that require precision cutting, engraving, and marking.

Let’s take a closer look at what a DC excited glass tube CO2 laser is, how it works, and some of its key advantages and disadvantages.

What is a DC excited glass tube CO2 laser?

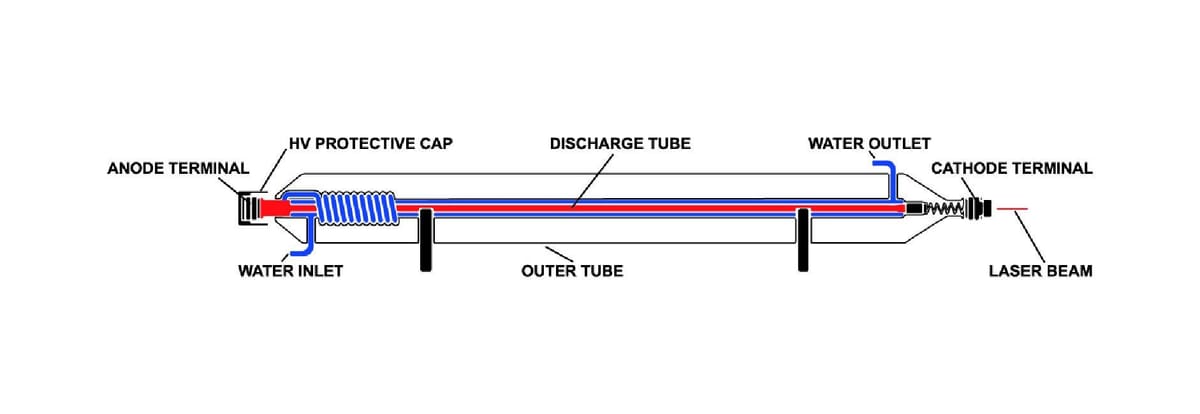

A DC excited glass tube CO2 laser is a type of gas laser that uses a mixture of carbon dioxide, nitrogen, and helium gases to produce a high-energy laser beam. The laser is called a “DC excited” laser because it uses a direct current (DC) electrical discharge to excite the gas mixture and create the laser beam.

The laser consists of a sealed glass tube filled with the gas mixture and two electrodes at either end of the tube. When a high voltage is applied across the electrodes, a discharge is created that excites the gas molecules and creates a population inversion. This population inversion leads to the emission of photons as the excited molecules return to their ground state, which produces the laser beam.

How does a DC excited glass tube CO2 laser work?

The operation of a DC excited glass tube CO2 laser can be broken down into four main steps:

- Excitation: When a high voltage is applied across the electrodes, a discharge is created that excites the gas molecules and creates a population inversion.

- Amplification: As the excited gas molecules return to their ground state, they emit photons. These photons are reflected back and forth inside the laser cavity by a pair of mirrors at either end of the glass tube. Each time the photons pass through the gas mixture, more of them are absorbed and re-emitted, leading to the amplification of the laser beam.

- Output: As the laser beam is amplified, it builds up to a high intensity and is reflected out of the laser cavity by a partially reflective mirror. This produces the laser output.

- Cooling: The laser tube and electrodes generate a significant amount of heat during operation, which can cause the gas mixture to break down and reduce the laser output. To prevent this, the laser tube is cooled using a flow of water or another coolant.

Advantages and disadvantages of DC excited glass tube CO2 lasers

DC excited glass tube CO2 lasers offer several advantages over other types of lasers, including:

- High power output: DC excited glass tube CO2 lasers can produce output powers of several kilowatts, making them suitable for a wide range of industrial applications.

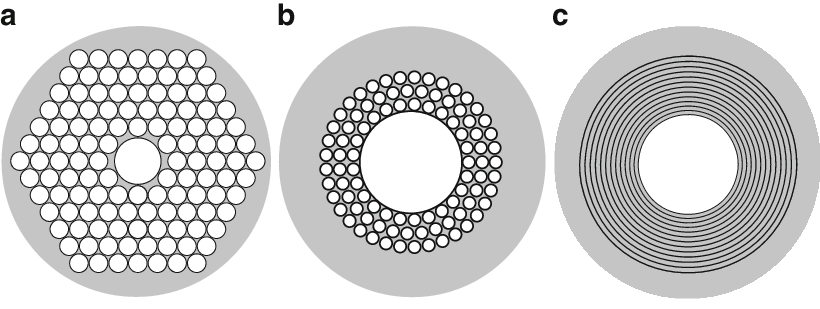

- Good beam quality: The laser beam produced by a DC excited glass tube CO2 laser has excellent beam quality, which means it can be focused to a very small spot size, making it ideal for precision cutting, welding, and engraving.

- Low maintenance: DC excited glass tube CO2 lasers are relatively simple in design and require minimal maintenance compared to other types of lasers.

However, there are also some disadvantages to using DC excited glass tube CO2 lasers, including:

- High cost: DC excited glass tube CO2 lasers can be expensive to purchase and operate, particularly at higher power levels.

- Limited wavelength range: DC excited glass tube CO2 lasers emit light at a wavelength of 10.6 micrometers, which limits their suitability for some applications that require different wavelengths.

- Hazardous gases: The gas mixture used in DC excited glass tube CO2 lasers contains carbon dioxide, which can be hazardous if not handled properly.

DC excited glass tube CO2 lasers are a popular type of laser found in most engraving machines on the market today. Using a gas mixture and high voltage to produce a beam powerful enough to blast through most materials, it’s become a staple in the industry.